OBTAINING LARGE COMPRESSION VOLUMES

Centrifugal compressors evolved from centrifugal fans and pumps, as well as aircraft turbines, and appeared in industrial applications in the early 20th century.

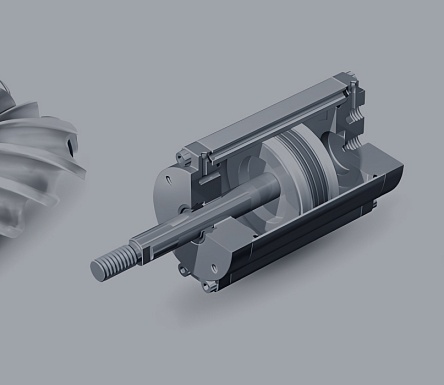

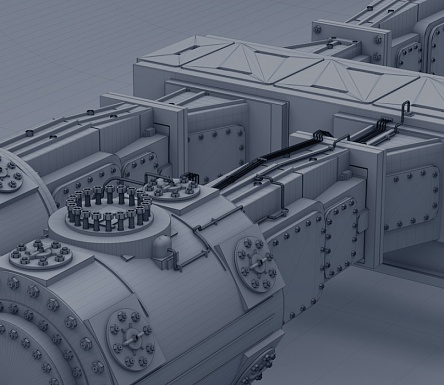

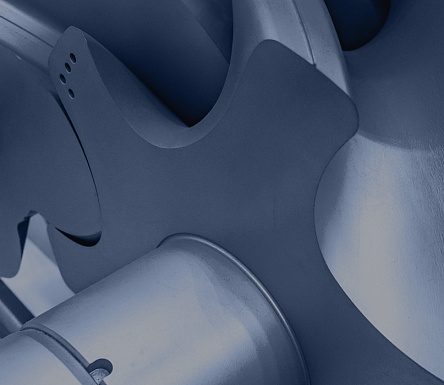

A centrifugal compressor is a multi-stage unit with an internal gear drive, which is driven by an engine. Each compression stage consists of a working wheel - an impeller, a diffuser, and a casing (volute). The gas is sucked in through an inlet filter and fed to the first compression stage through an inlet regulating device. Intermediate coolers are installed between all compression stages. Compressors can operate at 2 or even 4 compression stages with both a horizontal or vertical housing split. They are used mainly when it is necessary to obtain large compression volumes.

TYPES OF CENTRIFUGAL COMPRESSORS

By the type of stage arrangement, centrifugal compressors can be divided into:

SINGLE-SHAFT

Work in stable loading modes:

- Gas pumping

- Supply of stable flows of process gases in chemical and petrochemical production

- Oil and gas refineries

MULTI-SHAFT

Work in variable loading modes:

- Gas supply to gas turbines

- Supply of process gas flows changing in a wide range of flow rates in chemical and petrochemical production

- Oil and gas refineries

PURPOSE

- Transportation of natural gas through main gas pipelines

- Collection and transportation of associated petroleum gas

- Compression of petroleum gases during gas lift oil production

- Compression of associated petroleum gas in gas processing plant technology

- Gas injection into the formation during the development of gas condensate fields

ADVANTAGES

- Complete absence of oil in the working cavity and in the compressed medium

- Non-contact air and oil seals

- Complete absence of vibration

- No need for a special foundation

- Operation practically without pulsation

- Fewer rubbing elements

- Long term of continuous operation up to 5 years without stopping

DISADVANTAGES

- High investment cost of equipment

- Costs for cooling systems

- Costs for automation for the operation of cooling towers and pumps

- Costs for scheduled repairs and maintenance

OPERATING RANGE

- Power range: 500-35000 kW

- Volume range: 3000-1300000 m3/h

- Pressure: 0.3-1000 MPa

- Speed: 300-3000 rpm